Introduction

Inventory management is usually a simple process for most small retail businesses. But, as you go higher up the chain, and your customers and inventory holdings increase, managing all that stock by yourself becomes challenging.

Some business owners opt for vendor-managed (VMI) and supplier-managed inventory (SMI) systems to meet product demand. With the right partner, VMI and SMI systems can provide an effective means of inventory management, allowing you to focus on more critical business operations.

In this article, we evaluate vendor and supply-managed inventory systems, including their benefits and potential drawbacks.

What Is Vendor-Managed Inventory (VMI)?

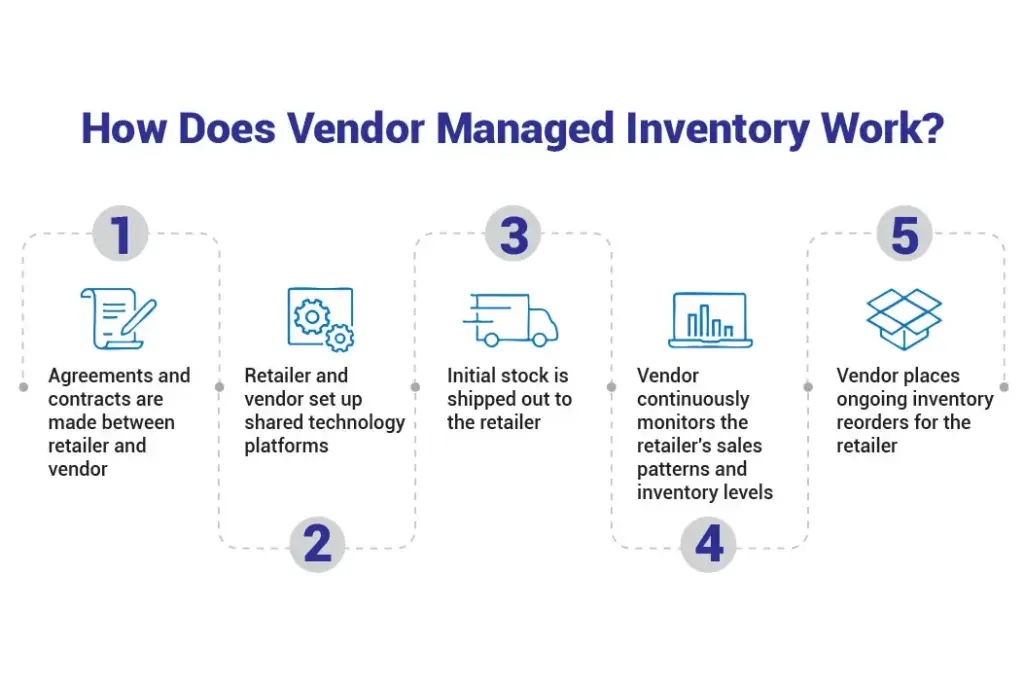

Vendor-Managed Inventory (VMI) is a collaborative inventory management system where the vendor takes responsibility for maintaining and replenishing your inventory. In this model, the vendor monitors stock levels, forecasts demand, and ensures that your business has the right amount of inventory at all times.

Key Benefits of VMI

- Reduced Workload: By outsourcing inventory management to the vendor, your team can focus on core business activities.

- Improved Efficiency: Automated systems minimize human error and streamline inventory processes.

- Cost Savings: VMI can reduce storage costs and prevent overstocking or stockouts.

- Enhanced Data Insights: Vendors often provide valuable analytics to help you make informed decisions.

Potential Drawbacks of VMI

- Loss of Control: You relinquish control over inventory decisions, which may not align with your business goals.

- Limited Flexibility: You’re tied to the vendor’s product offerings, which can limit your ability to diversify.

- Dependency on Vendor: Poor vendor performance can disrupt your supply chain and impact customer satisfaction.

What Is Supplier-Managed Inventory (SMI)?

Supplier-Managed Inventory (SMI) is similar to VMI but involves the supplier (often the manufacturer) managing your inventory. In this model, the supplier uses demand forecasts and inventory data provided by your business to adjust production and ensure optimal stock levels.

Key Benefits of SMI

- Flexibility: SMI allows for better alignment between production and demand, reducing the risk of overproduction.

- Cost Efficiency: Suppliers can optimize production schedules, leading to lower inventory costs.

- Stronger Supplier Relationships: Collaborative planning fosters trust and long-term partnerships.

- Reduced Lead Times: Suppliers can respond quickly to changes in demand, ensuring timely deliveries.

Potential Drawbacks of SMI

- Cost Creep: Hidden charges, such as management fees or higher product prices, can offset cost savings.

- Contractual Limitations: Switching suppliers can be difficult due to binding agreements, potentially limiting your options.

- Data Sharing Risks: Sharing sensitive business data with suppliers requires trust and robust security measures.

VMI vs. SMI: Key Differences

While both systems aim to streamline inventory management, they differ in several key areas:

| Aspect | VMI | SMI |

|---|---|---|

| Responsibility | Vendor manages inventory | Supplier manages inventory |

| Control | Less control for the retailer | More collaboration with the supplier |

| Flexibility | Limited to vendor’s offerings | Tied to supplier’s production capabilities |

| Cost Structure | Potential for hidden fees | Risk of cost creep |

| Relationship | Vendor-focused | Supplier-focused |

How to Choose Between VMI and SMI

Deciding between VMI and SMI depends on your business needs, goals, and relationship with your vendors or suppliers. Here are some factors to consider:

- Level of Control: If you prefer to maintain control over inventory decisions, SMI may be a better fit. If you’re comfortable outsourcing, VMI could work well.

- Product Complexity: For businesses with diverse product lines, SMI offers more flexibility. VMI is ideal for simpler, more standardized inventories.

- Supplier/Vendor Reliability: Choose a partner with a proven track record of performance and transparency.

- Cost Considerations: Evaluate the total cost of each system, including potential hidden fees or cost creep.

- Long-Term Goals: Consider how each system aligns with your business’s growth and scalability objectives.

Best Practices for Implementing VMI or SMI

Whether you choose VMI or SMI, follow these best practices to ensure success:

- Choose the Right Partner: Work with a vendor or supplier who understands your business and shares your values.

- Set Clear Expectations: Define roles, responsibilities, and performance metrics in a formal agreement.

- Leverage Technology: Use inventory management software to track stock levels, forecast demand, and analyze data.

- Monitor Performance: Regularly review the system’s effectiveness and address any issues promptly.

- Maintain Communication: Foster open communication with your partner to build trust and resolve challenges quickly.

Both Vendor-Managed Inventory (VMI) and Supplier-Managed Inventory (SMI) offer powerful solutions for businesses looking to streamline inventory management and focus on growth. While VMI provides convenience and efficiency, SMI offers flexibility and stronger supplier collaboration. The right choice depends on your business’s unique needs, goals, and relationship with your supply chain partners.

By carefully evaluating the benefits and drawbacks of each system and implementing best practices, you can optimize your inventory management process and drive long-term success.

Elevate Your Brand Packaging

Craft packaging that makes your products shine

Get started today!